MACHINING. MACHINING. MACHINING.

It's what we do

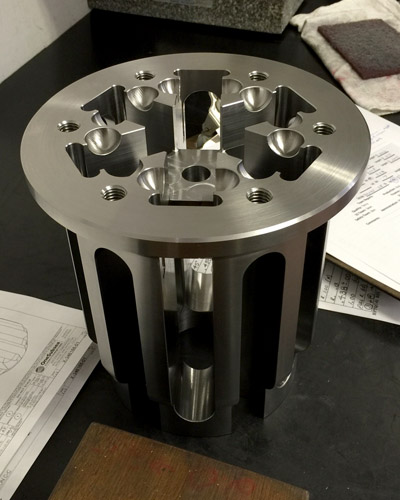

Highpoint Tool and Machine does Precision Machining for the aerospace and oil & gas Industries, using the latest CNC equipment and high technology tooling. We precision machine components to customer designs from stainless steel, inconel, aluminum, titanium, carbon steel, cast iron and engineered resins/plastics.

Highpoint’s machining processes are controlled by our registered ISO 9001:2015 and AS9100D quality systems.

Our experience integrating our customers quality requirements from material procurement through post processes and delivery gives us the added capability of providing the documentation package you need to satisfy your traceability requirements.

The career minded precision machinists at Highpoint are excellent at what they do, and their pride shows in the components they produce for our customers every day. Each machinist is involved in our continuous improvement program, constantly learning new technologies and sharing with co-workers.

HIGHPOINT TOOL AND MACHINE

MACHINING the parts you want.

Highpoint Tool and Machine is your best source for your precision machining requirements. Our machinists are proud of what they do and constantly undergo new and additional training to keep up with the latest cutting tool technologies, software improvements, and machine tool operation techniques. Our state of the industry machine tools are maintained in top working condition for safety and productivity, and upgraded as required to capitalize on technology advancements. Our facility constantly exercises 5S methodology to keep everything safe, clean and in its place.

The equipment at Highpoint can handle machining parts up to 40″ or 300lbs. One of a kind or prototype parts are as normal for us as repeat orders and production runs. We run small lots from 1- 40 pieces, as well as small production runs of 40- 1,000 pieces.

Highpoint’s top CNC machinists specialize in prototype work, developing new parts with customers engineers and providing machinability input during product design. Our 5 axis mill-turns with sub spindles provide “done-in-one” capabilities, valuable for making changes during prototype and development work.

The custom parts that Highpoint produces are programmed using MasterCam and Esprit CAM software to generate our tool paths, working from Customer supplied digital models, drawings, conventional prints or even reverse engineering. If a digital model is not provided, we can create one using SolidWorks. Highpoint machinists are comfortable precision machining highly engineered alloys like Inconel and other stainless steels, titanium, aluminum, brass, and carbon steel, bar stock as well as forgings and castings, also composite’s, nylons and even cast iron. Documents are controlled from Quoting and Order Entry through Material acquisition and certification not only to provide complete Documentation Packages for the Customer, but to assure our job Routers are accurate, efficient and complete.

Highpoint’s receiving area stores incoming material and is equipped with an automatic saw for bar stock preparation. All material is certified and controlled.

HIGHPOINT TOOL AND MACHINE

MACHINING the parts you want.

Highpoint Tool and Machine is your best source for your precision machining requirements. Our machinists are proud of what they do and constantly undergo new and additional training to keep up with the latest cutting tool technologies, software improvements, and machine tool operation techniques. Our state of the industry machine tools are maintained in top working condition for safety and productivity, and upgraded as required to capitalize on technology advancements. Our facility constantly exercises 5S methodology to keep everything safe, clean and in its place.

The equipment at Highpoint can handle machining parts up to 40″ or 300lbs. One of a kind or prototype parts are as normal for us as repeat orders and production runs. We run small lots from 1- 40 pieces, as well as small production runs of 40- 1,000 pieces.

Highpoint’s top CNC machinists specialize in prototype work, developing new parts with customers engineers and providing machinability input during product design. Our 5 axis mill-turns with sub spindles provide “done-in-one” capabilities, valuable for making changes during prototype and development work.

The custom parts that Highpoint produces are programmed using MasterCam and Esprit CAM software to generate our tool paths, working from Customer supplied digital models, drawings, conventional prints or even reverse engineering. If a digital model is not provided, we can create one using SolidWorks. Highpoint machinists are comfortable precision machining highly engineered alloys like Inconel and other stainless steels, titanium, aluminum, brass, and carbon steel, bar stock as well as forgings and castings, also composite’s, nylons and even cast iron. Documents are controlled from Quoting and Order Entry through Material acquisition and certification not only to provide complete Documentation Packages for the Customer, but to assure our job Routers are accurate, efficient and complete.

Highpoint’s receiving area stores incoming material and is equipped with an automatic saw for bar stock preparation. All material is certified and controlled.

HIGHPOINT TOOL AND MACHINE

Our Mission

A company uses a mission statement to maintain focus and keep all continuous improvement efforts consistent. Here at Highpoint our mission statement also reflects our belief that our employees carry equal weight as our customers when addressing corporate concerns and direction. Every Highpoint employee is a professional and his/her future is considered equally with that of the customer and company. The content of our mission statement is what drives our company, it is what we are trying to achieve, every day.

Highpoint Tool & Machine Mission:

Highpoint Tool and Machine will partner with our Customers, providing them with perfect quality products and services, delivered exactly when they want them. Our employees will enjoy coming to Highpoint every day, constantly learning and improving processes, while satisfying their own personal career goals.